Some details of precision injection mold

- Categories:IndustryNews

- Author:

- Origin:

- Time of issue:2023-05-25 14:40

- Views:

(Summary description)Here are some additional details about precision injection molds:Tight Tolerances: Precision molds can achieve part tolerances of 0.001 inches or less. They produce dimensionally accurate plastic parts with minimal variation between pieces. Consistent wall thicknesses and uniform shrinkage are also possible.

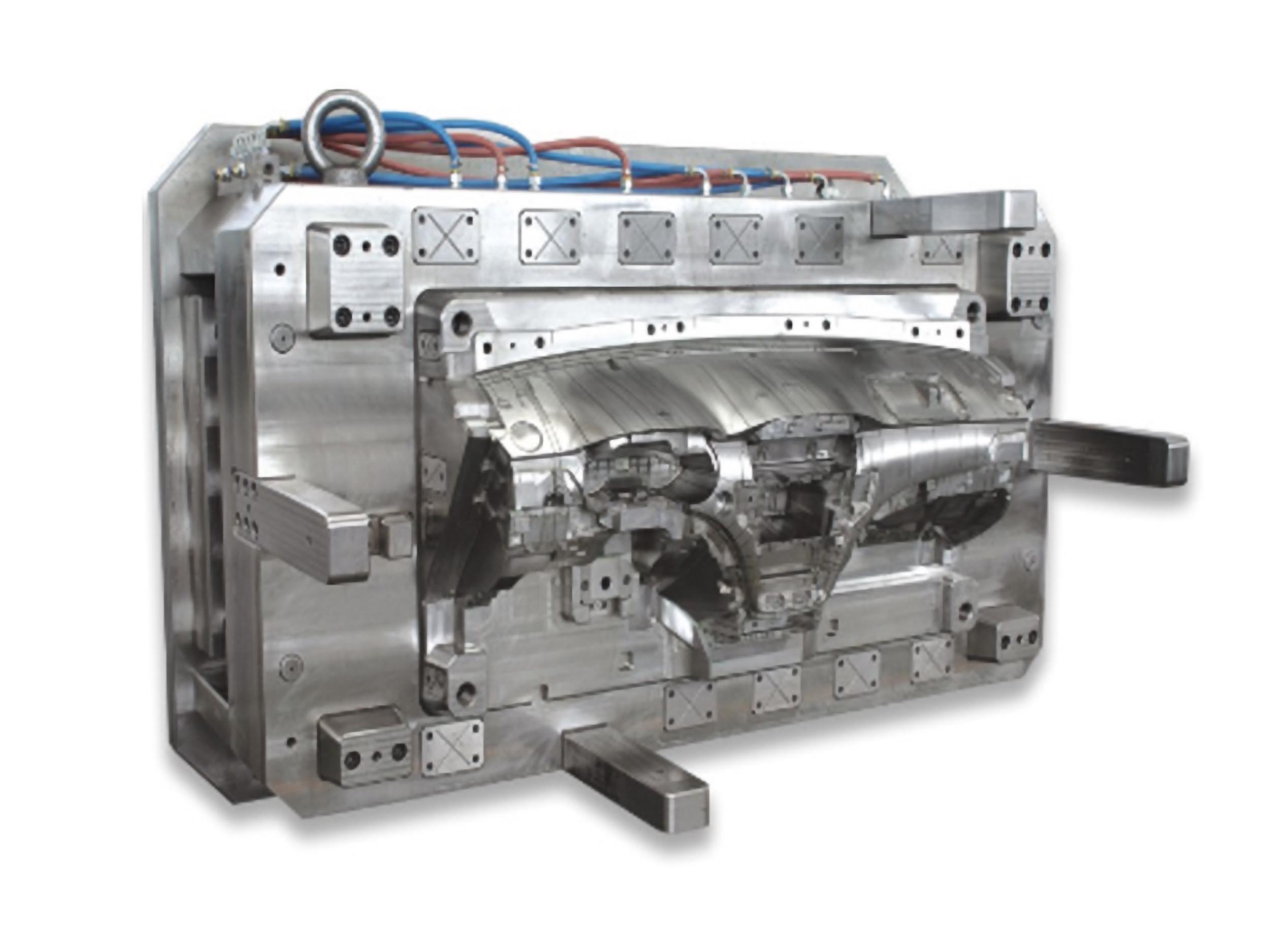

Some details of precision injection mold

(Summary description)Here are some additional details about precision injection molds:Tight Tolerances: Precision molds can achieve part tolerances of 0.001 inches or less. They produce dimensionally accurate plastic parts with minimal variation between pieces. Consistent wall thicknesses and uniform shrinkage are also possible.

- Categories:IndustryNews

- Author:

- Origin:

- Time of issue:2023-05-25 14:40

- Views:

Here are some additional details about precision injection molds:

Tight Tolerances: Precision molds can achieve part tolerances of 0.001 inches or less. They produce dimensionally accurate plastic parts with minimal variation between pieces. Consistent wall thicknesses and uniform shrinkage are also possible.

Smooth Surface Finishes: Precision molds yield plastic parts with mirror-like surface finishes through polishing and treatments like chrome plating or diamond coating. Surface finishes of 0.5 Ra or better can be achieved.

Complex Geometries: Precision molds can incorporate actions such as side cores, collapsible cores, unscrewing cores, and cube molds to enable undercuts, holes and other complex features. They expand the design possibilities for injection molded plastics.

Repeatability: Precision molds provide highly repeatable results from shot to shot due to strict controls over molding conditions like temperature, pressure, speed and time. They minimize variations between production runs to ensure consistent quality and performance in the plastic parts.

Premium Materials: Precision molds require the use of high-grade tool steels, aluminum alloys or other wear-resistant metals to withstand high injection pressures while retaining close dimensional accuracy over thousands of molding cycles. Chrome or nickel plating is often used to increase surface hardness and wear resistance.

Advanced Equipment: Precision injection molding machines provide precise monitoring and control of molding parameters for both consistency and flexibility in processing. Robots or CNC equipment are commonly used to transfer parts to minimize human handling and potential damage after molding.

Secondary Operations: Additional processes like CNC machining, laser cutting, drilling or ultrasonic welding may be required to achieve final part dimensions or features. Precision molds facilitate these secondary operations by providing close tolerances and optimal plastic properties as a starting point.

Higher Cost: Due to the expensive materials, tight tolerances, complex actions and skilled labor required, precision molds typically cost 2 to 5 times more than standard molds. Precision injection molding also demands premium plastics, additives and equipment - all of wh ich increase part costs relative to conventional molding. However, precision molds enable the production of innovative plastic parts with higher performance and quality. For specialized applications, the added costs are often justified.

In summary, precision injection molds open up new possibilities for plastic part design that demands the highest accuracy and repeatability. Although costlier and more difficult to develop compared to standard molds, precision molds provide an array of benefits for the production of intricate, m ission-critical components used in advanced industries. They represent an important technology for high-end plastics manufacturing.

Related News