Technology of precision injection mold

- Categories:IndustryNews

- Author:

- Origin:

- Time of issue:2023-05-19 14:37

- Views:

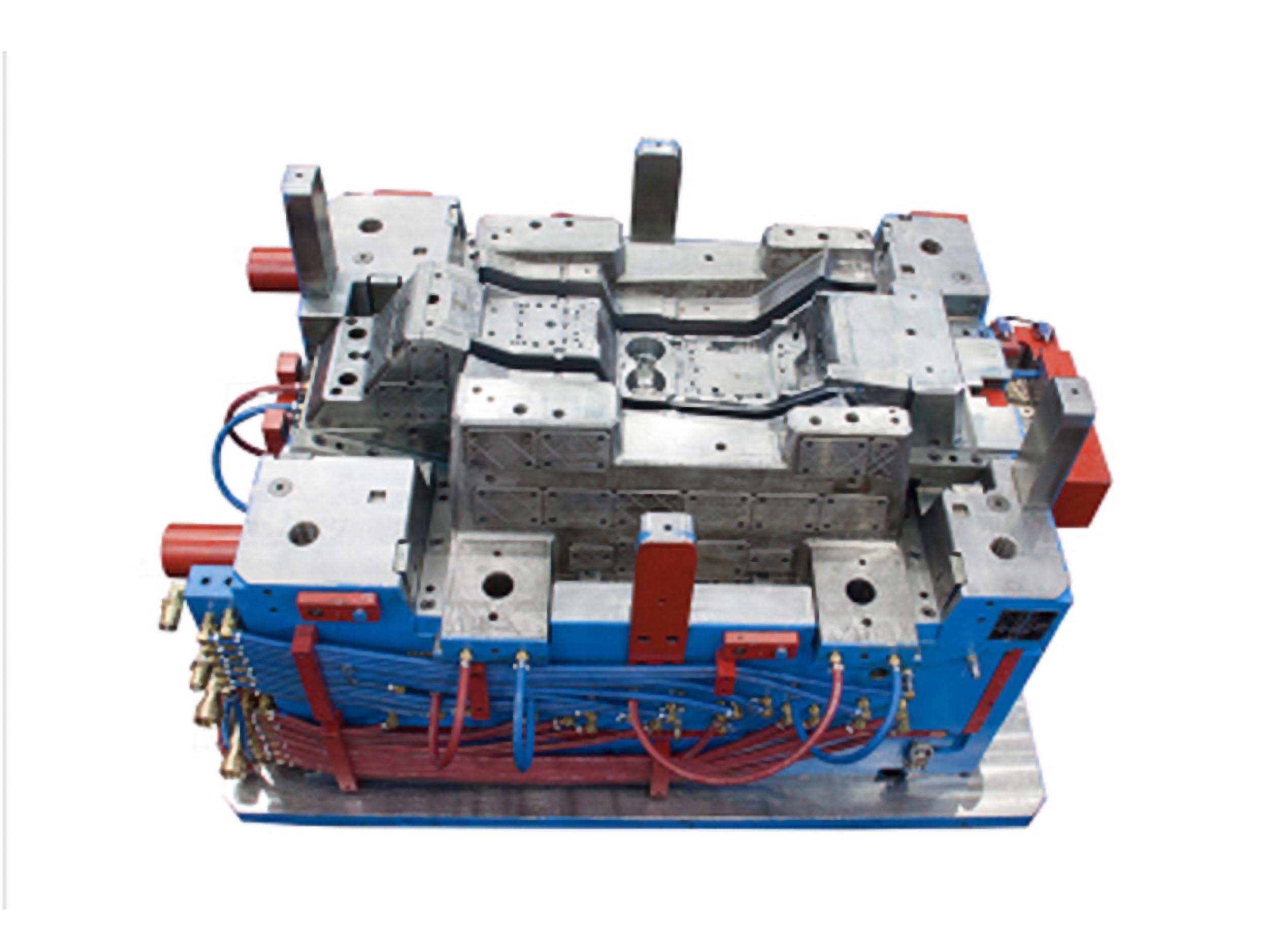

(Summary description)A precision injection mold is a customized mold tool used in plastic injection molding to produce parts with tight tolerances and complex geometries. It is made of high grade steel alloys for high precision and durability. Precision molds require advanced CNC machining and polishing techni ques to achieve the close tolerances and smooth surface finishes necessary for precision plastic parts.

Technology of precision injection mold

(Summary description)A precision injection mold is a customized mold tool used in plastic injection molding to produce parts with tight tolerances and complex geometries. It is made of high grade steel alloys for high precision and durability. Precision molds require advanced CNC machining and polishing techni ques to achieve the close tolerances and smooth surface finishes necessary for precision plastic parts.

- Categories:IndustryNews

- Author:

- Origin:

- Time of issue:2023-05-19 14:37

- Views:

A precision injection mold is a customized mold tool used in plastic injection molding to produce parts with tight tolerances and complex geometries. It is made of high grade steel alloys for high precision and durability. Precision molds require advanced CNC machining and polishing techni ques to achieve the close tolerances and smooth surface finishes necessary for precision plastic parts. They enable the production of plastic components with precise dimensions, details and configurations that cannot be achieved through standard molding.

Precision injection molds are significantly more expensive to design and manufacture versus conventional molds due to the higher material costs and hours of skilled labor required. However, they are essential for producing critical components where accuracy and repeatability are important. Common applications include medical devices, aerospace components, optical lenses, gears and other high-performance parts.

Precision molds provide tighter control of injection pressure, temperature, speed and other process parameters to yield optimal molding results. They often incorporate moving sections, core pulls, and collapsible cores to enable undercuts and hole features in the plastic parts. Tem perature control channels are built in into the molds to facilitate uniform heating and cooling. Surface treatments such as chrome plating or diamond polishing are applied to give plastic parts with smooth mirror-like finishes.

The precision injection molding process requires the use of advanced plastics, reinforced alloys and additives to withstand elevated stresses from high pressure molding without compromising accuracy or surface finish. Carefully calibrated injection molding machines that provide precise control and repeat atability are also essential. Secondary operations like CNC Machining, laser cutting or ultrasonic welding may be necessary to achieve final part specifications.

In summary, precision injection molds produce plastic parts with tight geometrical tolerances and complex features that demand the highest levels of accuracy and repeatability. They represent a sizable investment for the development and manufacturing of precise, intricate components used in spec ialized applications where high performance and quality are critical. Precision injection molding involves the use of premium mold tools, plastics, additives and equipment to yield optimal results. It often requires advanced secondary operations to complete the precision components. While costly and time-consuming, precision inj ection molds enable innovative plastic parts that push the limits of design and performance. They provide an important method for high-tech plastics manufacturing.

Related News