What are the processes of precision injection mold

- Categories:IndustryNews

- Author:

- Origin:

- Time of issue:2023-03-17 11:18

- Views:

(Summary description)Precision injection mold refers to a device that injects resin material into a metal model to obtain a product with a certain shape. Precision injection molds are mass-produced parts with complex shapes using precision processing methods.

What are the processes of precision injection mold

(Summary description)Precision injection mold refers to a device that injects resin material into a metal model to obtain a product with a certain shape. Precision injection molds are mass-produced parts with complex shapes using precision processing methods.

- Categories:IndustryNews

- Author:

- Origin:

- Time of issue:2023-03-17 11:18

- Views:

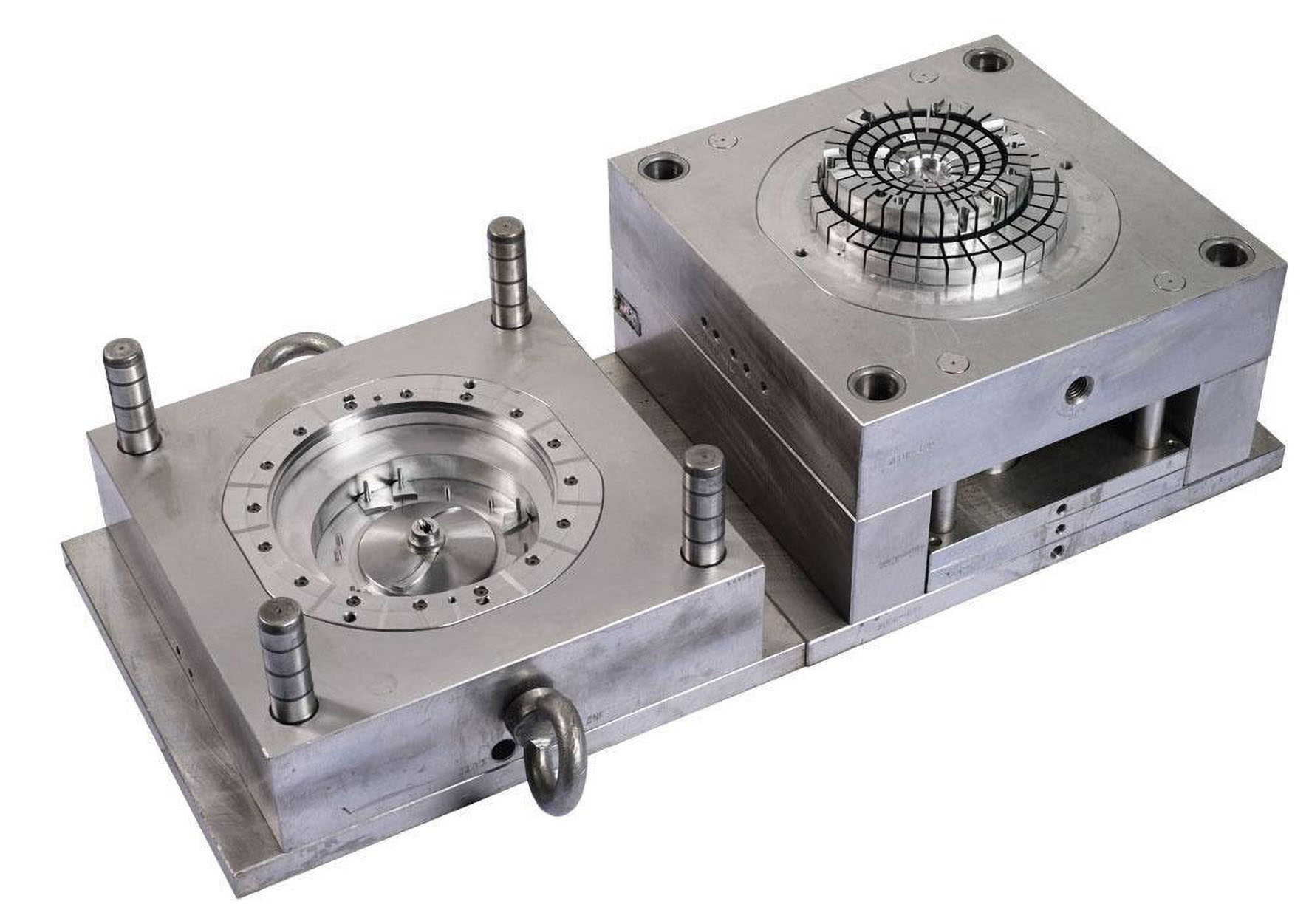

Precision injection mold refers to a device that injects resin material into a metal model to obtain a product with a certain shape. Precision injection molds are mass-produced parts with complex shapes using precision processing methods. Specifically, the heat-melted material is injected into the mold cavity by high pressure, and after cooling and solidification, various molded products are obtained.

Precision injection molding means that the appearance accuracy of injection molded products should meet strict dimensional tolerances, shape tolerances and surface roughness. The manufacturer of precision injection mold tells you that there must be many related conditions for precision injection molding, and the most essential are the four basic factors of plastic material, injection mold, injection molding process and injection molding equipment. When designing plastic products, engineering plastic materials should be selected first, and engineering plastics capable of precision injection molding must choose those materials with high mechanical properties, stable dimensions, good creep resistance, and environmental stress cracking resistance. The manufacturer of precision injection mold tells you that the appropriate injection molding machine should be selected according to the selected plastic material, the dimensional accuracy of the finished product, the weight of the piece, the quality requirements and the expected mold structure.

Related News